Selecting the right manufacturer for all-in-one solar street lights is a decision that greatly influences the success, dependability, and sustainability of your projects. In a fast-growing market with myriad offers, pinpointing a genuinely proficient and reliable partner requires due diligence. This guide aims to assist in evaluating manufacturers against key differentiating criteria that distinguish the best from the rest while ensuring performance consistency. Consider this not merely as purchasing, but as establishing an alliance that will illuminate neighborhoods for generations to come.

Finding Right Manufacturer

The market for all-in-one solar street lighting is a mix of opportunities and challenges. Projects like municipal infrastructure improvements, large commercial construction projects, and rural electrification are increasingly using these independently powered solar lights. The market’s plethora of manufacturers presents a unique challenge—the varying degrees of expertise, quality control, and service make for a daunting selection process. It’s analogous to searching for a specific star in a crowded night sky without any guidance.

Identifying potential suppliers is easy, but choosing a supplier who can consistently offer highest quality products, technical innovation, and dependable support requires a more in-depth approach. This guide aims to arm you with the tools and understanding needed to go beyond the simple supplier lists and conduct a detailed analysis to help you find a manufacturer that fulfills your project requirements—and surpasses expectations.

Assessing Core Capabilities & R&D

A manufacturer’s core capabilities—production scale, manufacturing processes, supply chain management, and critically, its investment in Research and Development (R&D)—form ). These factors cumulatively define his ability to reliably produce high-quality goods, satisfy market demand, and continuously relocate in an aggressive technology-centered environment. A vigorous R&D department acts as the innovation spearhead seeking how to enhance efficiency, durability, and ease of use.

To evaluate manufacturing capability, one must first assess the scope of their operations—do they possess the capacity to manage the volume your project requires? Modern facilities equipped with automated processes denote technological sophistication and commitment to precision which improves product quality over manual assembly lines. Strong Supply Chain Management (SCM) guarantees timely procurement of high quality components which, in turn, enhances the productivity of the assembly processes, avoid bottlenecks, and safeguard the quality of the end product.

Research and development (R&D) is the heart of innovation in solar and LED technology. A manufcturer who invests greatly in R&D will most likely be leading the market in refining energy terminals, advancing battery technology, smart control systems, and developing backup systems. To evaluate a manufacturer’s R&D strength, consider the scope and background of the technical squadra, the portion of revenue allocated to R&D each fiscal year, the pace at which new creative solutions are brought to market, and their patent portfolio. These are indicators of a commpany that actively anticipates new challenges in the field of solar lighting.

Detailed Technical Checks Matter

When developing the design of an all-in-one solar street light, the challenge often lies with the technical aspects. The concept is straightforward in relation to the integration of components, but warranty period and functionality, including advanced features like integrated sensors and IoT connectivity, depend on the internal components and their synergy. Diligent technical assessment is not merely wishing on the spec checklist; it’s living through these components in terms of how they work as a single unit and what quality is for each. Components are best understood as building blocks in order to focus your attention on the right features; you can witness with your own eyes what happens if even a single component is faulted.

Pay attention to the important components, which include:

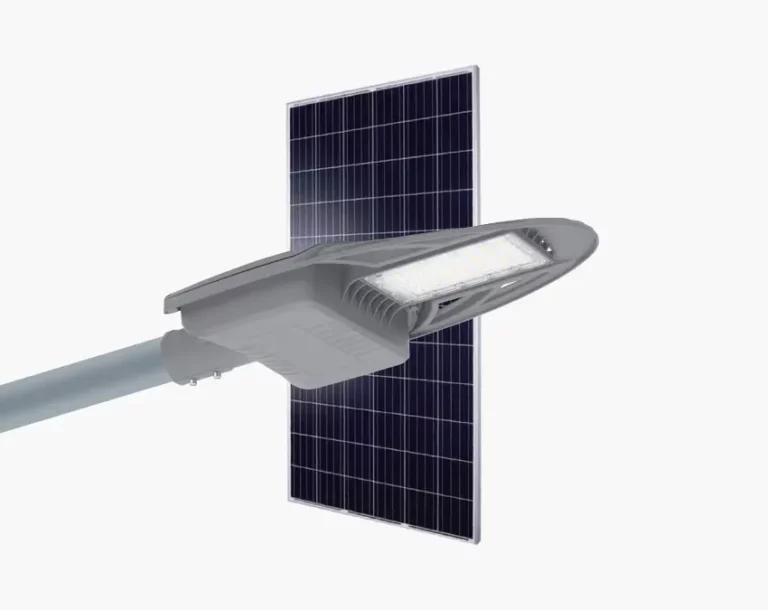

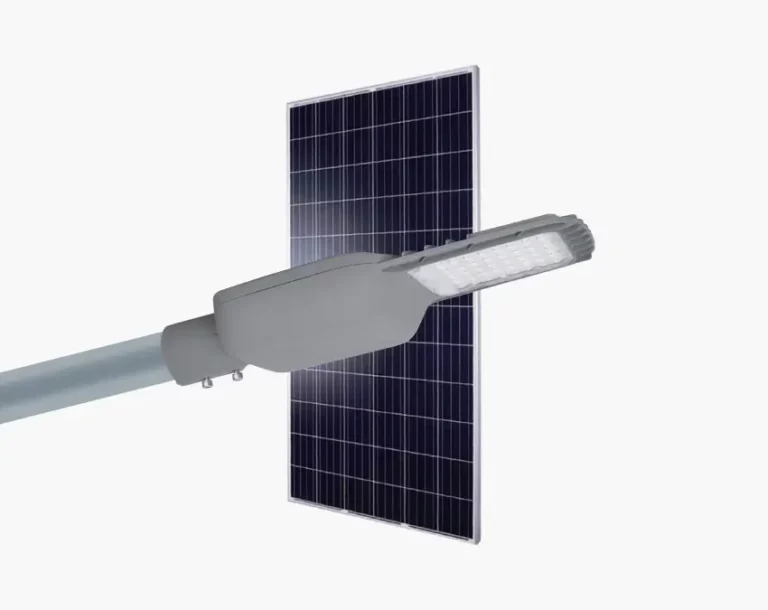

- Solar Panel: Not every solar panel manufacturer is at the same level. A reputable company captures every opportunity to harness energy from limited sunshine in poor weather, such as during cloudy days, by investing in grade A solar cells with high conversion efficiency.

- Battery: The battery in this scenario functions like the heart of the system – it preserves its energy reserve until the sun sets. The first order of business for these lithium battery units is to make sure that they are lithium iron phosphate, aka LiFePO4, due to unrivaled safety and cycle life. It will be equally important to appreciate the system BMS (battery management system). BMS’S main role is to save the battery from excess charge, shallow discharge, and unhealthy temperatures.

- LEDs: Quality of the LED chips (brand, efficacy, CRI – such as Cree LED chips) and the LED fixture’s thermal management cooling directly influences the light output, brightness, uniformity (light distribution), and the lifespan of the LED. Achieving high brightness and optimal lifespan requires effective heat dissipation from the LED module. Pay attention to specifications like lumens and wide lighting angle to ensure the light covers the intended area effectively.

- Controller: The solar charge controller does power flow regulation, accordingly optimizing the charging and discharging. However, MPPT (Maximum Power Point Tracking) controllers tend to outshine PWM (Pulse Width Modulation) controllers in efficiency. Smart functions to look out for include dimming profiles, general sensor capabilities (like microwave motion sensor), remote control options, and IoT integration, along with most importantly, multi-protection features for system safety, as offered in Inluxsolar intelligent solar controllers.

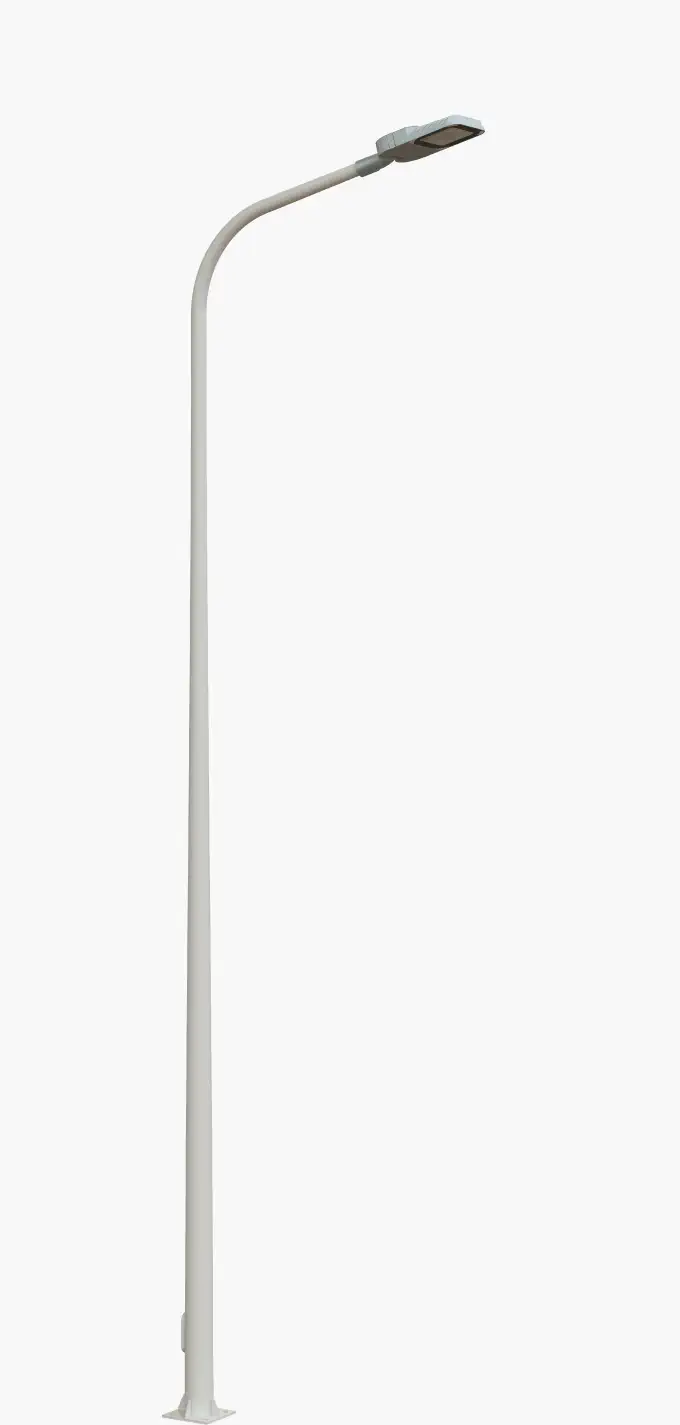

- Structure and Fixture: The mechanical resistance and physical structure of the product are extremely important for external use. Key elements include the material of the housing (anti-rust aluminum alloy case is preferred), impact safeguarding, ingress protection (IP) from dust and water, and the structural strength of the light poles and their brackets. These components must collectively provide confidence to withstand harsh environments for long-term sustained performance. Consider design features like a rotatable LED module which can enhance flexibility in light aiming. Furthermore, advanced models may integrate additional features like CCTV cameras (cctv functionality) for enhanced security.

The combination of the properly integrated and selected high quality components contributes to the reliability of the product.

Verifying Quality & Certifications

Certifications act as key markers, providing guarantee checkpoints as to a manufacturer’s compliance with industry standards and other requisite norms. ISO 9001 mark proves that the company has in place quality management processes. The CE and RoHS certifications are equally relevant for the European market regarding safety and the use of hazardous substances. The IP (Ingress Protection) and IK (Impact Protection) ratings conducted by independent laboratories are vital for a fixture’s offshore usability and ruggedness.

Certifications, however, mark the beginning rather than the culmination of quality assurance. A dependable manufacturer goes beyond external certifications by integrating strong internal Quality Control (QC) systems. This includes the examination of raw materials during receipt inspection, step wise inspection at the production line, and testing of the sample from the lot. There are various validation processes designed to lessen the product’s reliability risks and these include aging tests, vibration tests, and environmental chamber tests among others.

Without direct pointers, verifying a manufacturer’s claims requires the submission of detailed QC flowcharts, test documents for key constituents and finished products, and perhaps arrangement of a walk-through the factory setup. Providing and documenting open access suggests these are confident in their processes and these are reasonable signs of their dedication.

Understanding Warranty Deeply

A manufacturer’s warranty is not simply a count of years offered; it represents the manufacturer’s confidence in the product and its longevity as well as his commitment to uphold the warranty. In the case of infrastructure projects that extend over many years, a good warranty in conjunction with reliable after sales service provides effective safety nets, or rather, insurance offers for your investment.

A warranty should not be considered at face value. A warranty should be understood to what exact parts are included (is the battery warranty separate? Are the terms for the panel and the leds and the controller the same?), what are the possible terms which may constitute a cancellation of the warranty (e.g., improper installation, modifications), and what is the procedure to be given in order to fill a warranty claim. Is the manufacturer responsive? What is the agreed time for repair or brand new unit?

Supporting the malfunctioning features is only one dimension; look at the general after-sales attention. Is there a help desk for installation and for troubleshooting? Are the necessary spare parts easily accessible? Will they come if the situation demands it? The manufacturer who adds value by offering such wide ranging support aids in reducing outages whilst safeguarding your investment.

Getting True Product Value

If solar street lights are only evaluated on their purchase price, detriment is inevitable. Their true worth is captured using Total Cost of Ownership (TCO) encompassing all costs associated over the life of the product. Products that appear cheaper at first glance may result in higher costs over time because of constant breakdowns, expensive upkeep, poor efficiency, and early need for replacement. This is akin to observing the tip of an iceberg with no consideration for the larger structure lying underneath the surface that is concealed.

Assessing true product value considers the lifespan and reliability of key components such as batteries and LEDs, failure rates, maintenance (well-designed all-in-one units require less), and performance across all environments. The initial price may be steep but the ROI will outlast the operational life, the added performance will offset operational concerns and replacement expenses, and ease achieved will prove invaluable.

Steps Towards Partnership

After you have assessed a prospective manufacturer for his capability, technology, quality, and after-sales service, you can now start a working relationship with him. Like all good business practices, forming a working relationship with a manufacturer usually begins with a defined process which streamlines the work from the first step to the last step. A process can be regarded as a very precise compass guiding one through very complex terrain.

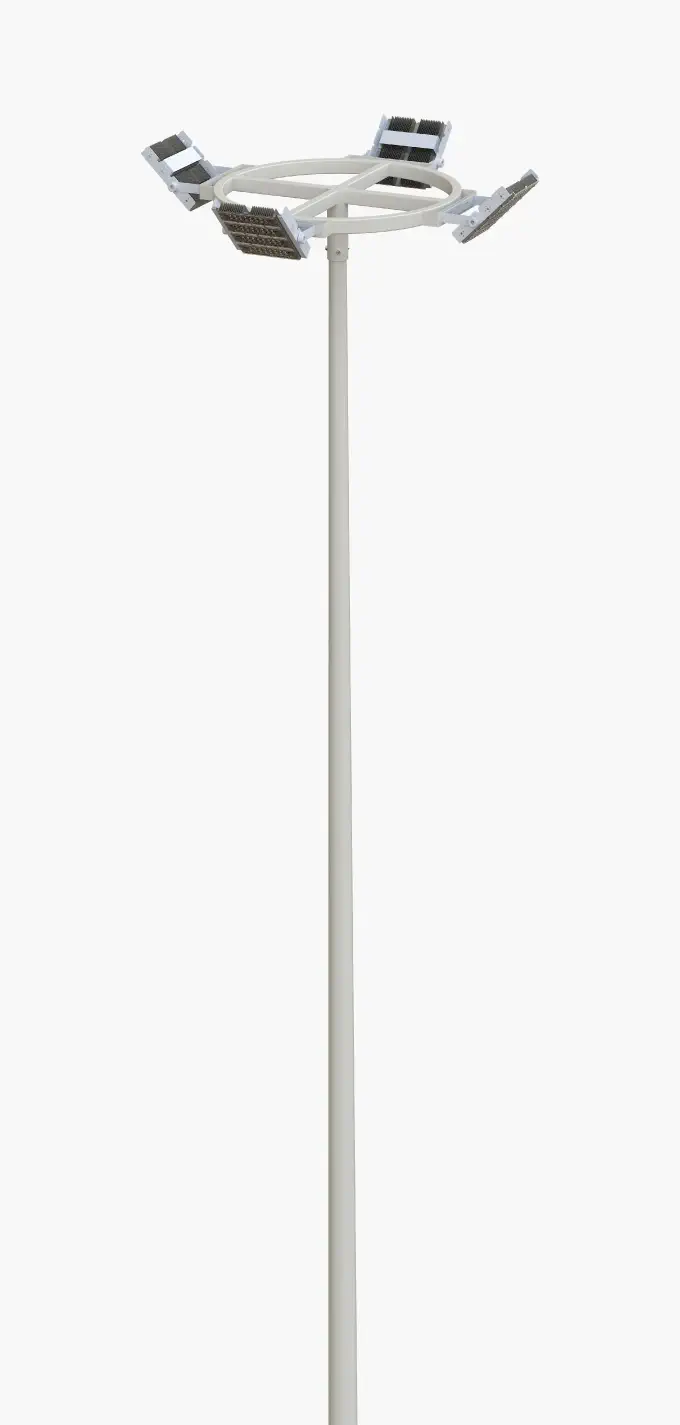

Many journeys start with the customer’s detailed inquiries, defining project scopes (whether for solar parking lot lighting, commercial solar lighting, or systems for rural roads, highway lighting, and other roadways), and asking for cost estimates along with technical proposals that may include details on necessary accessories. Evaluation of samples is often a critical step which helps to verify quality and performance claims. After Negotiation and Contract signing, the manufacturer goes on to define his production plan. Each stage in production requires a crucial quality inspection. This is true from the beginning until shipment. Professional manufacturers wait to install and commission the product and their commitment continues on with after-sales service and potential lifecycle support.

It is sometimes most advisable to involve a manufacturer at the earliest time possible in a project’s life cycle, while in the bidding or even design phases for example. This is particularly true when developing solutions for specific applications like parking lot lighting.It is easier for a manufacturer with a rich technical team to assist you, as they are able to do photometric simulations and structural calculations which are custom tailored to the design. Custom tailored technical documents are meant to win bids, not designed for optimized lighting solutions. A sure engagement of not merely minor adjustments is proof of engineering commitment to meet unique project demands at a higher level.

Leading 6 Industry Manufacturers

Considering the assessment factors mentioned which include: R&D, technical quality, certifications, warranty, service, and overall capability, the global market has a number of manufacturers with a commanding presence in the all-in-one solar street light segment. This list is exemplary and does not purport to be complete as there are many other companies which are equally reputed and have established reliability in the market. All prospective clients must tailor their research according to their defined parameters in order to make the right decision for their projects.

Here are six leading industry manufacturers to consider:

Signify (Philips)

Signify, a worldwide pioneer in lighting, attaches solar capabilities to their professional lighting solutions. Integrating into smart city frameworks, their extensive R&D and established history in lighting technology helps them manufacture robust products. Signify’s brand recognition and distribution network strengthen their market presence.

Leedarson Lighting

One of the largest in the lighting industry, Leedarson, also excels in OEM/ODM mass production. With capacities to receive large orders, they specialize in many markets and global brands by designing and manufacturing a range of products including integrated solar solutions with a highly efficient supply chain.

Greenshine New Energy

Greenshine focuses on solar lighting solutions and supplies diverse systems for parks, pathways, parking lots, and streets. They specialize in tailored solar project designs and configurations which help serve the North American market.

Sepco Solar Electric Power Company

Specializing in solar power system, Sepco develops dependable off-grid solar lighting for challenging remote environments, merging rugged design with reliability. Their world leading expertise in integrating solar energy informs other infrastructure projects making them a renowned name for off-grid deployments.

HES Manufacturing(HES PV)

HES PV operates in the renewable energy industry specializing on solar energy systems and solar lighting solutions, providing services to clients demanding reliable off grid power and lighting systems, especially in some regional markets. Durability is often designed into their systems.

Inluxsolar

Inluxsolar specializes on manufacturing high quality integrated solar street lights. The company is known for its use of first class materials, strong R&D as evidenced by numerous patents, industry leading warranty and lifecycle services, and comprehensive tailored solutions with extensive project support offered internationally.

These manufacturers illustrate an important part of the market that usually insists on quality and service. Whatever your requirements are, will determine which manufacturer is more suitable for your project.

Based on these varied strengths, the manufacturers mentioned above may be particularly well-suited for certain types of projects or needs. The following table provides a general guide:

| Project Need / Audience Type | Recommended Manufacturer(s) | Reason for Recommendation |

| Large-Scale / Global Projects | Signify, Leedarson, Inluxsolar | Global presence/distribution, high production capacity, extensive project experience. |

| High Reliability / Harsh Environments | Sepco, HES PV, Inluxsolar | Focus on robust designs, off-grid expertise, use of high-quality materials for durability. |

| Projects Requiring Deep Customization | Inluxsolar, Leedarson, Greenshine | Strong OEM/ODM capabilities, tailored solutions approach, in-house design expertise for specific needs. |

| Municipal & Infrastructure Projects | Signify, Sepco, Inluxsolar | Experience in large-scale infrastructure, focus on reliable systems for public spaces, project support capabilities. |

| UN & NGO Projects | Inluxsolar | Specific stated experience and support for UN/NGO tender requirements and project types. |

| Seeking Balance of Quality & Value | Inluxsolar, Leedarson | Commitment to high-quality materials/processes balanced with potentially competitive offerings from scale/efficiency. |

| Prioritizing Long-Term Support & Warranty | Inluxsolar, Signify | Industry-leading warranty offer, comprehensive lifecycle/global service availability, established support networks. |

Note: This table provides general guidance based on the strengths highlighted. Thorough individual evaluation is always recommended.

Meet a Reliable Partner

In searching for a suitable all-in-one solar street light manufacturer, one has to consider their capabilities, product quality, and service in relation to your project requirements and long-term expectations. While the features of a number of strong players in the industry have been given in the examples and table above, it is important to also look at the manufacturers who, in our experience, consistently meet the highest standards for all the evaluation criteria.

Inluxsolar is remarkable as an integrated solar lighting manufacturer who provides unparalleled comprehensive high quality integrated solar lighting solutions. This is achieved through their committment to their business by investing into a proven R&D team of over 10 experts, each with an average of 15 years of experience, who are guaranteed innovation due to 5% of annual sales revenue reinvested into R&D, 60 patents and 300 product test reports further proving their innovation claim.

Unmatched with their uncompromising prioritization of first-class materials, to achieve their goal of 0.5% failure rate, they also use Grade A solar cells, ultra-bright LEDs with a lifespan of over 50,000 hours, anti-rust aluminum fixtures with IP66-IP67 rust protection rating and IK09-IK10 structural impact protection rating, hot dip galvanized poles rated for 30m/s wind resistance, and smart controllers with multiprotection functions which guarantees high performance.

Inluxsolar’s customer services along with quality of products offered sets them apart in the industry. Their unrivaled 3-5 year system warranty, which is further complimented by Lifecycle Services like on-site service worldwide, puts them ahead of industry competitors who usually provide only 2-3 years of warranty. They also provide quick responses, offering quotes within 6 hours and delivering most orders within 15 days.

Inluxsolar showcases its expertise with Worldwide Impact, demonstrating over 1000+ global projects. They efficiently cater to Municipal, UN, and Commercial projects, assisting in bid evaluation, performing high accuracy photometric simulations (95% accurate), structural calculations, and customized solutions. Their clients are guided with a structured 14-Step Roadmap from Bidding to Project Acceptance which allows clients to navigate smoothly through the process and secure projects. In addition, the company’s in-house design permits tailored project not merely standard alterations to precise specifications.

By choosing Inluxsolar, you ensure technical finesse, unmatched support and assistance, documented quality, and years of solar street lights project experience. If you wish to illuminate your project with meticulously integrated solar street lights, feel free to witness our unparalleled dedication to quality and service.

Inluxsolar looks forward to discussing your project prerequisites and explaining how our solutions provide value when you contact us today.